What Is Quartz Made Of? Inside the Engineered Process

Engineered, But Not Artificial

When people hear the word ‘engineered’ in the context of quartz countertops, they sometimes assume it means fake, or somehow less than natural stone. But here’s the truth: engineered quartz is built from one of the hardest, most durable minerals on Earth, natural quartz. It’s not a knockoff. It’s a purpose-built product designed to deliver strength, style, and consistency.

We’ve worked with quartz for years now, and we’ve seen just how far the technology has come. If you’re curious about what exactly goes into these countertops, here’s a closer look—straight from the shop floor to your kitchen.

So, What Is Quartz Made Of?

Engineered quartz slabs are made from about 90–95% crushed natural quartz, blended with resins and pigments to create a solid, uniform surface. The result? A highly durable material that’s non-porous, low-maintenance, and available in just about any color or pattern you can imagine.

Here’s a quick breakdown of the core ingredients:

- Natural Quartz: This is the base of the product. Pure quartz is typically white or translucent and incredibly hard—perfect for surfaces that see a lot of use.

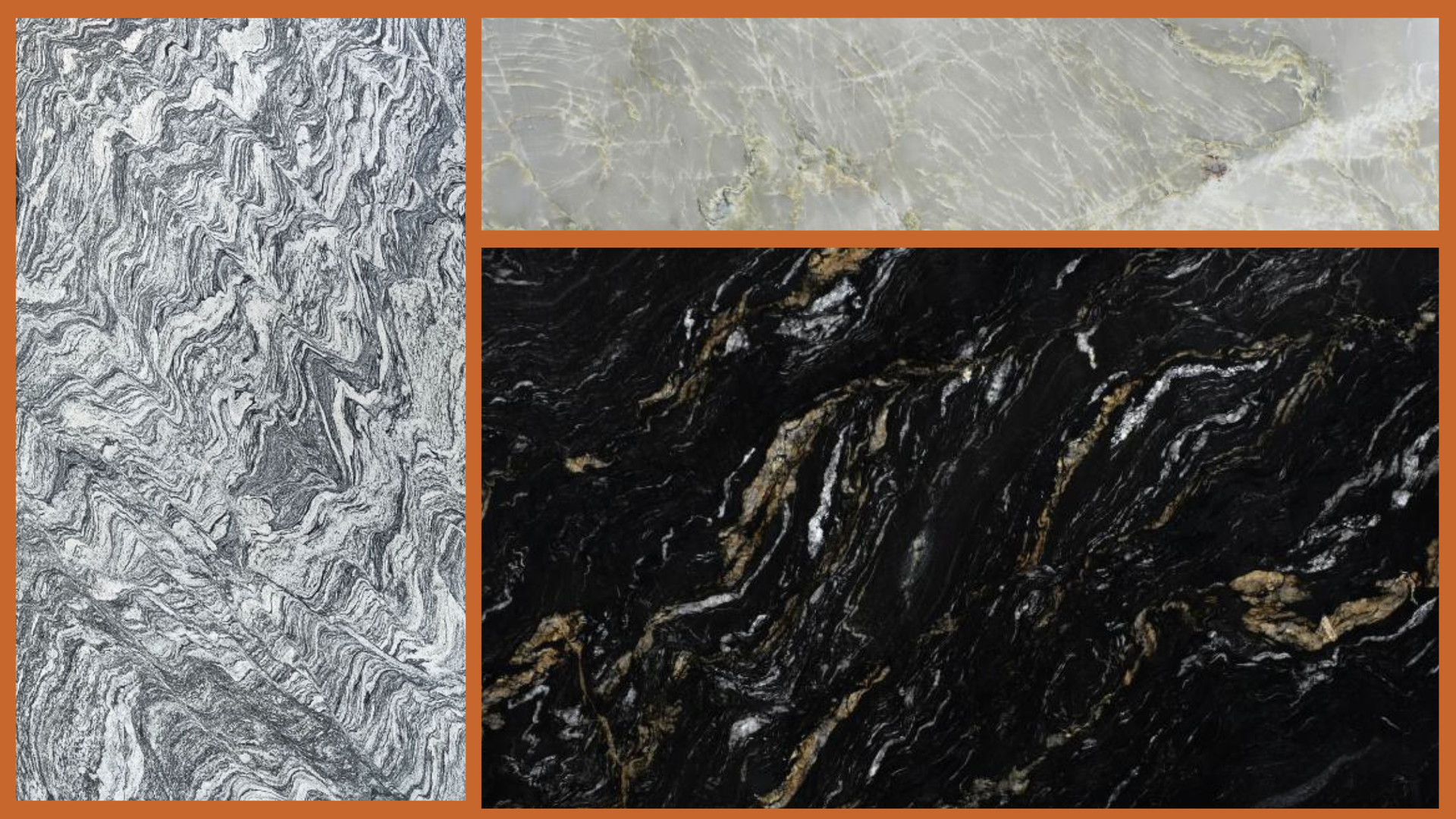

- Pigments/Dyes: To get all those beautiful colors and patterns, manufacturers use colorants to tint the quartz. These can range from subtle creams and grays to deep blues, greens, and bold, marbled mixes.

- Resin Binders: These act like the glue that holds everything together. They also help create that smooth, sealed finish that makes quartz resistant to stains, moisture, and bacteria.

The real magic happens in how these components come together.

Inside the Manufacturing Process

Every quartz manufacturer has their own twist on how they make their slabs, but the general steps are pretty similar across the board. Here’s a simplified look at the engineered process:

- Crushing & Mixing: Raw quartz is ground down into different sizes—some fine like sand, others more coarse for texture. It’s then blended with pigment and resin in large mixers.

- Molding & Compression: The mix is poured into molds and pressed using vibration and vacuum systems to eliminate air bubbles and make sure it’s completely compacted.

- Curing: The slab is baked at high temperatures to harden and set the resin. This turns the mixture into a dense, solid surface.

- Cutting & Polishing: Once cured, the slabs are trimmed to size and polished to create different finishes—from glossy to matte to leathered textures.

- Quality Control: Each slab is inspected for color consistency, structural integrity, and surface finish before heading out to fabricators like us.

The slabs typically come in what we call jumbo sizes, around 65 inches by 130 inches. That gives us plenty of flexibility to design for kitchens, bathrooms, and other spaces without awkward seams or waste.

Why Choose Quartz?

Every material has its strengths. Quartz has become popular for a reason—it gives people the look they want with the performance they need. We see it chosen most often by homeowners who want:

- A consistent look across large surfaces

- Low maintenance (no sealing needed)

- Stain and scratch resistance

- Modern colors and marbling that mimic natural stone

- Durability that holds up over time

And because quartz is engineered, you’ll find more pattern control and repeatability, something that’s tough to guarantee with natural stone.

Designed with Intention

Quartz isn’t a shortcut. It’s a smart material for people who want the look of stone without the unpredictability. It’s engineered, yes, but it’s engineered with intention, using one of nature’s strongest elements as its foundation.

If you’ve been curious about quartz and whether it’s right for your project, come walk through our showroom. We’ll walk you through the options, show you some slabs in person, and help you decide what feels right.

Bring a sketch and come see us. Let’s find what makes you feel good.

Designing Surfaces For Your Life

Share On: