How to Maintain the Shine of Your Granite Countertops

Matt Greenlee • June 12, 2025

When someone walks into a kitchen with polished granite, it turns heads. There’s just something about that deep, reflective finish that says, “This space matters.” But if you’ve ever wondered how to keep that shine looking like day one, you’re not alone—and you’re not wrong to ask.

We’ve been fabricating and installing granite countertops

here in Prescott for 27 years. And one of the first things customers ask after install is, “How do I keep it looking this good?” Good news: it’s not hard. You just need to know a few key things.

It Starts with Cleanliness

We always say the best maintenance is a clean countertop. Daily wipe-downs go a long way—just a soft cloth and mild soap will do. Granite is tough, but grit and grime left sitting can start to dull that surface over time.

Think of it like this: your countertop is already polished to a mirror finish. The goal is to protect that polish—not redo it.

Understanding What "Shine" Really Means

That glossy look isn’t from a coating—it’s from the stone itself. When we polish granite, we’re using finer and finer abrasives (think of it like super high-grit sandpaper) to smooth the surface until there are no visible scratches. The fewer scratches, the more the light reflects—and that’s your shine.

If you drag something across that surface—especially metal or something gritty—you’re introducing scratches bigger than the ones already there. That’s how shine gets lost.

What to Watch Out For

Most of the time, folks aren’t ruining their counters with one big mistake. It’s the little things repeated over time. Here are a few habits to stay aware of:

- Avoid sliding pots, pans, and cast iron across your granite. These can carry abrasives from the stovetop or food that act like sandpaper.

- Don’t drop your grocery bags down if they’ve been sitting on the ground. Dirt stuck to the bottom of a bag is enough to dull the finish.

- Keep your countertops dry when possible. Water rings can collect dust and minerals that slowly build up if not wiped clean.

- Use trivets and cutting boards. Granite is strong, but the surface polish benefits from a little respect.

Regular Maintenance, Simplified

You don’t need fancy products or a complicated routine. If you follow these simple steps, your counters will keep their luster for years to come:

- Wipe up spills daily using a soft cloth and mild soap.

- Use a granite-specific cleaner weekly if you want to boost that shine.

- Avoid harsh chemicals or abrasive scrubbing pads.

- Consider resealing once a year (ask us if your granite needs it).

When the Shine Starts to Fade

Every stone surface has a lifespan, but the good news is: granite can always be brought back. If your countertop has dulled over time or taken some abuse, give us a call. We can often restore that shine with a little professional TLC.

We interpret a lot of that all the time. You might not need a full resurface—just a good clean and polish.

The Real Secret? Respect the Stone

Granite is a natural material, and part of its beauty is that it’s unique. It has movement, depth, and texture that’s unmatched—and it deserves care that honors that.

We always tell folks: treat your countertop like a centerpiece. Because in most homes, it is.

Still Have Questions?

Come see us. Bring a sketch. Bring a question. Heck, bring a picture of a spill you’re not sure how to clean. We’re here to help—whether you bought your countertop from us last week or ten years ago.

Designing Surfaces For Your Life

There’s a lot of confusion out there when it comes to porcelain and ceramic tile . The two look similar, and most folks don’t think about the difference until something chips, cracks, or starts peeling off in the cold. Here in Prescott, where our temperature swings can be dramatic and unpredictable, understanding this difference isn’t just helpful, it’s essential. Because when tile fails, it’s not always the installer or the grout. Sometimes, it’s the material itself, and whether it was the right one for the job. It All Comes Down to Water Absorption Here’s the number one difference: water absorption. Ceramic tile absorbs more water. That’s fine for indoor, dry environments. But in Prescott, where we deal with freeze-thaw cycles, that water can become a real problem. Once moisture gets into the tile body and then freezes? There’s no stopping it. “There really isn't a force on this planet that is as extreme as water freezing.” It expands, and it breaks the tile from the inside out. Porcelain tile, on the other hand, has a much lower absorption rate, less than half of one percent. That makes it the best choice for outdoor areas, wet spaces, and anywhere exposed to extreme shifts in temperature. Freeze-Thaw Is No Joke Here in Prescott, it might be 18 degrees when you leave for work and 65 when you get home. If you’ve got tile outside, or even on a poorly sealed shower wall, those temperature shifts start to matter. Ceramic tile starts spalling (the glaze pops off), mortar separates, and soon your beautiful tile job looks like it’s been through a war. That’s why we always recommend porcelain tile for: Outdoor patios Entryways Shower walls with high exposure Any space that sees temperature fluctuation or consistent moisture We’ve seen the damage that happens when people use the wrong product in the wrong place. And we’ve fixed it, more times than we can count. It’s Not Just About Durability Durability matters, but there’s more to consider. Each material has its own look, feel, and design strengths . And that’s where we help homeowners get creative, while still making smart choices. Here’s a quick breakdown: Porcelain Tile Lower water absorption (less than 0.5%) Best for outdoor or wet areas Allows for large format tiles without warping (12x24, 24x24 and larger) Harder, more dense, and frost-resistant Realistic stone and wood looks via inkjet glazing Ceramic Tile Higher absorption (5–7%) Best used indoors and on walls Often hand-painted or decorative Offers more glaze and color variety More affordable for certain applications We’ve got some ceramic tiles in our showroom that are absolute stunners—especially for backsplashes and decorative borders. But when it comes to function-first spaces, porcelain’s the workhorse. Large Format, Less Grout Another reason people lean toward porcelain these days is grout. Nobody loves cleaning it, especially not in showers. With porcelain, you can go bigger with tile sizes, which means fewer grout lines and a more seamless, modern look. We’re even seeing full porcelain panels being used in showers, big sheets like 5’x10’. Or in some cases, customers are choosing half-inch engineered quartz slabs for shower walls to get that zero-grout look with silicone seams instead. It’s a clean, timeless option that works great in Prescott’s climate. Tile You Can Trust—And Live With Choosing between porcelain and ceramic tile isn’t about trends or price tags. It’s about where it’s going, what it’s going to face, and how long you want it to last. We’ve spent decades learning these materials, not just in theory, but by installing them, maintaining them, and sometimes...replacing them when others got it wrong. If you’re not sure what’s best for your home, come walk the showroom. We’ll help you sort through it. You don’t have to be a tile expert, that’s what we’re here for. Bring a sketch and come see us. Let’s find what makes you feel good. Designing Surfaces For Your Life

Bathrooms are one of those spaces where design and durability have to live side by side. A shower might be small on square footage, but it’s big on daily use—and it’s where materials really get put to the test. When customers ask us what’s “in style,” we always bring the conversation back to something more lasting: What’s going to look good ten years from now? And just as important, what’s going to hold up in Prescott’s unique environment? Let’s talk through some shower tile ideas that balance beauty, function, and timeless appeal, based on what we’re actually seeing work in homes right here in our community. Patterns That Endure If you walk through our tile section today, one thing you’ll notice is how many people still gravitate toward offset patterns. Also known as a brick joint or a 33% offset, it’s a layout that softens the look of long rectangular tiles and keeps your eye moving without feeling too busy. We’re also seeing a return of random staggered layouts, especially when people want to avoid symmetry that feels too formal. These layouts create flow and feel a little more relaxed, which works beautifully in bathrooms that blend modern and rustic styles. And no matter the layout, accent bands are still going strong—both horizontal and vertical. These little design choices give a shower personality without overwhelming the space. Large Format Tiles = Less Grout If you’ve lived in Prescott for a while, you know our hard water doesn’t play nice with grout. That’s why large format tiles are having a moment—not just for aesthetics, but for maintenance. We’re seeing more and more homeowners choosing 12x24 or even 24x48 tiles in their showers. The bigger the tile, the fewer grout lines you have to scrub. And for folks who really want a seamless, slab-like look, we’re even installing full porcelain panels that run floor to ceiling in a single piece. More than a trend, it’s a solution to a real problem. Less grout means less to clean, fewer spots for mildew to hide, and a sleeker overall feel. Materials That Make a Difference When it comes to choosing tile materials for showers, durability and water resistance are key. That’s why porcelain tile continues to be our top pick. It has a super low absorption rate, which means it won’t soak up moisture and start breaking down over time. In other words—it won’t come apart on you. But there’s also a growing interest in engineered quartz shower walls. With quartz now being fabricated in half-inch slabs, it’s easier to handle and install in vertical spaces. These slabs practically eliminate grout lines altogether and offer a clean, modern look that’s as durable as it is beautiful. We’re working on a few showers right now using these half-inch quartz slabs. Besides the shower floor (which still needs some texture for slip resistance), the walls are all sleek, solid surfaces with silicone joints instead of grout. It’s stunning—and it solves a lot of the maintenance headaches people have had with tile over the years. Features That Feel Personal What we love most is helping homeowners design a shower that feels like them . And the details matter. Here are a few elements we’ve been incorporating more often: Vertical mosaic bands for a spa-like vibe Recessed niches that blend into the tile for a cleaner look Mixed textures like matte body tile with glossy accents Natural stone-look porcelain that brings warmth without the upkeep Silicone-seamed quartz slabs for a grout-free finish These choices blend functionality with style, creating a shower that will stand the test of time and look beautiful in your home. Let’s Design a Shower That Holds Up Timeless doesn’t have to mean boring. It means making smart design choices that feel good now and still feel right years down the road. Whether you lean classic or modern, we’ll help you find the balance of style, durability, and ease of maintenance that works in your life. Come walk our showroom . Touch the tile. See the slabs. Let’s find what speaks to you. Bring a sketch and come see us. Let’s find what makes you feel good. Designing Surfaces For Your Life

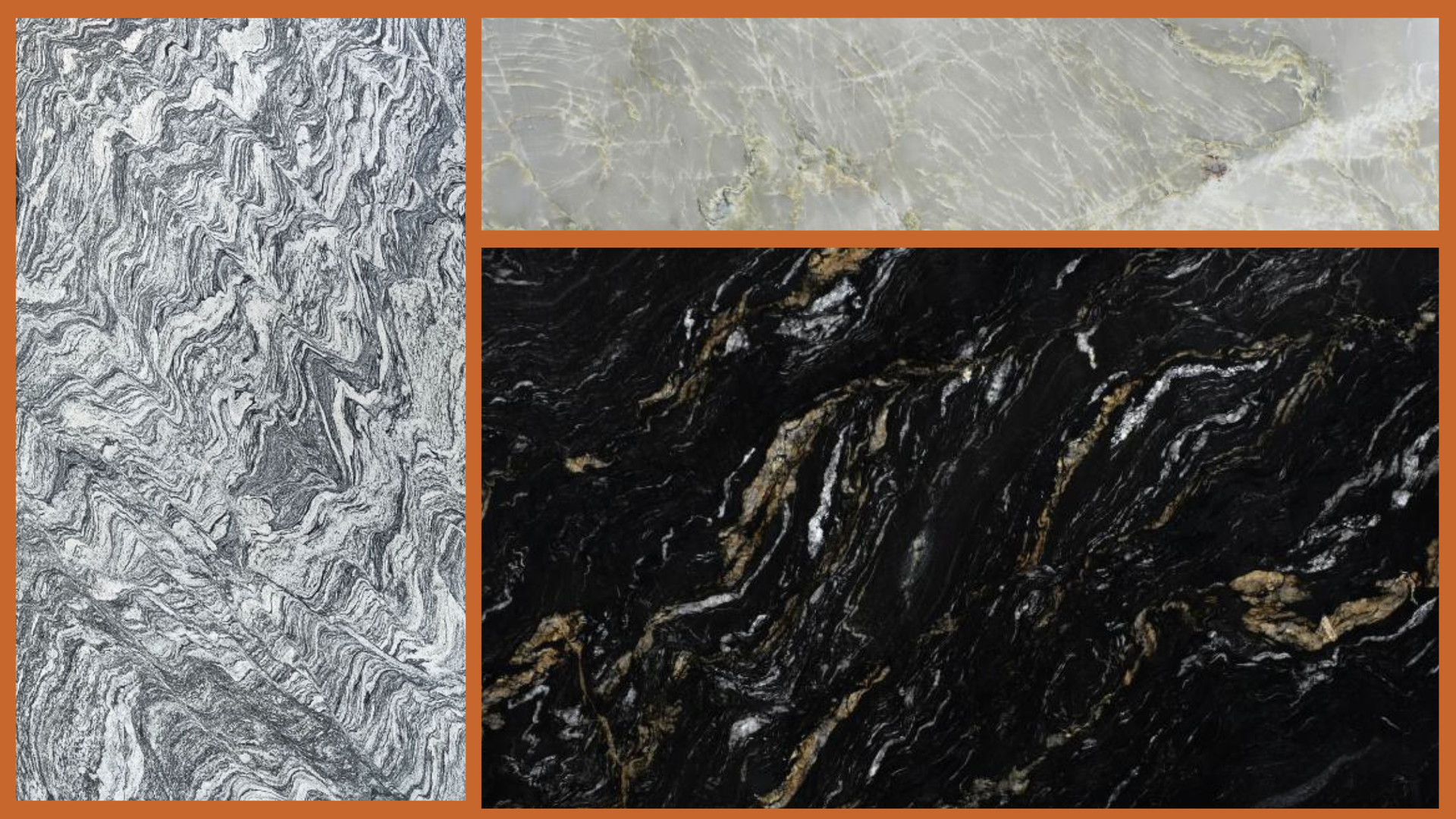

When you choose a natural stone countertop , the finish plays a big role in how it looks, feels, and functions in your space. Whether you're remodeling a kitchen or designing a custom bath, understanding the difference between polished, honed, and leathered finishes helps you make the right decision for both style and daily use. At Greenlee, we walk through this with every customer—because your surface should feel as good as it looks, and last just as long. What a Finish Really Does A stone’s finish changes how it reflects light, resists wear, and responds to touch. The same slab of granite or marble can have a completely different personality depending on how it's finished. Polished surfaces shine and reflect, honed ones are smooth and matte, and leathered textures bring out natural movement and grain. Choosing a finish is part of making your surface fit the way you live. Polished: Classic and Reflective This is the most common finish you'll see in kitchens and bathrooms. A polished stone has a glossy, mirror-like surface that enhances the depth and color of the stone. It’s smooth to the touch and easy to clean. Polished finishes are a great fit for traditional or upscale spaces where you want the countertop to make a visual impact. They’re also highly resistant to stains and moisture when properly sealed. What to consider: A polished surface will show fingerprints and smudges more easily, especially on darker stones or in high-traffic areas. If you're after low-maintenance shine, we’ll guide you to the right stone to match. Honed: Soft and Subtle A honed finish is smooth but not shiny. It has a matte or satin appearance that works well in contemporary, rustic, or transitional spaces. Honed finishes soften the color and pattern of the stone, offering a more muted, refined look. These surfaces are great in bathrooms or spaces where you want less glare and more texture. Honed finishes also make imperfections or etching less noticeable—especially on marble or lighter stones. Keep in mind: Honed stone can be slightly more porous than polished, so we recommend sealing it regularly. That said, if you're drawn to a softer, low-sheen aesthetic, this finish is hard to beat. Leathered: Textured and Natural Leathered finishes are growing in popularity—and for good reason. This process creates a lightly textured surface with a soft, tactile feel. It’s a great way to add depth and dimension without the high gloss of a polished slab. Leathering brings out the natural character of the stone—especially in darker granites—and hides fingerprints, water spots, and smudges better than polished or honed. It also adds a more organic, lived-in feel to kitchens and outdoor spaces. Things to know: Leathered surfaces aren’t totally smooth, so they may not be ideal for every task or material. That’s something we’ll walk through with you based on your layout and lifestyle. Which One Fits Your Life? Your finish should match how you use the space, not just how it looks in a showroom. That’s why we spend time getting to know what you’re designing, how you cook, clean, and live in your home. Here’s how to start narrowing it down: Polished: Best for formal kitchens, baths, and showpieces Honed: Ideal for soft, relaxed spaces or natural light rooms Leathered: Great for hiding wear, adding texture, and grounding the design Think about lighting—natural light can exaggerate shine or flatten matte surfaces Consider who’s using the space—kids, guests, entertaining all play a role Bring cabinet and flooring samples—we’ll look at everything together The Greenlee Difference We help design natural stone finishes to fit your life. That includes walking you through samples, showing how each finish reacts to light, and sharing what we’ve seen work in similar homes across Prescott. You don’t have to go to Phoenix. Bring your ideas and come see us in Prescott—we’ll help you find a finish you’ll love for years. Designing Surfaces For Your Life

Not all granite is created equal. For custom homeowners building or remodeling in Prescott, choosing the right slab isn’t just about the aesthetic—it’s about performance, precision, and long-term satisfaction. At Greenlee , we’ve spent 27 years helping customers see and feel the difference that quality granite makes. Here’s what to know when selecting the right slab, and why it pays to work with a local, in-house fabricator who knows how to guide you through it. What You Can’t See in a Slab Photo Granite looks beautiful in online galleries and showrooms, but quality goes beyond appearances. Two slabs of the same color may vary in density, veining, durability, and polish integrity. That’s why material selection should always be done in person, with expert guidance. When you walk our yard, you’ll see and touch the actual slab that’s going into your home—not just a sample. You’ll get to inspect the finish, check for consistency, and evaluate whether the movement and color will enhance the flow of your space. Why 3cm Granite Makes a Difference At Greenlee, we use 3cm material as our standard because it’s the right material for long-lasting, high-end countertops . That extra thickness means no need for a plywood subtop, which eliminates one more thing that could fail over time. It’s also more rigid and better able to support weight across large spans like islands. Beyond function, 3cm just looks better. It delivers the substantial, finished feel that high-end kitchens and baths deserve. Our Process Protects Your Vision Because we fabricate and install everything in-house, we can control the outcome from start to finish. That means we’re not guessing what your material will look like once it’s cut—it’s all mapped out with your goals in mind. Here’s how we help ensure your slab is the right fit: We walk the yard with you and point out natural characteristics in each stone. We help you understand how your lighting, cabinet tones, and layout will interact with the slab. We template with precision so we can lay out each cut to highlight the best parts of the stone. We finish the edges with craftsmanship you can feel—no shortcuts, no handoffs. What to Watch Out For Some suppliers may show you a slab but send a different one to fabrication. Or they may outsource the cutting and installation, leaving you without a clear point of contact if something goes wrong. That’s not how we work. When you choose Greenlee, you’re getting the team that selects, fabricates, installs, and stands behind your countertops—right here in Prescott. No middlemen. No runaround. Here are a few red flags to avoid when selecting granite: Slabs that feel overly porous or rough to the touch Inconsistent polish or pitting on the surface Thin (2cm) material requiring additional support Lack of transparency about where and how the slab will be fabricated Quotes that leave out edge profiles, seam placement, or installation details It’s a Big Investment—We Treat It That Way Your countertops aren’t just another line item, they’re a focal point in your home. They need to perform under daily use, look beautiful in every light, and last for decades. That’s why we take the time to walk you through every step, from slab selection to install day. I’m a rock hound. I fall for every pretty rock I find—but I also know what makes one slab a better investment than another. Our goal isn’t to sell you stone. It’s to help you choose the one that fits your space, your lifestyle, and your long-term needs. Bring a sketch. Ask questions . Come see us. Designing Surfaces For Your Life

When people ask me about quartz, they’re almost always trying to make a choice that will hold up—not just physically, but stylistically. I hear things like, “I don’t want something that’s going to look dated in five years,” or, “Is this finish going to stick around?” After 27 years of working with homeowners, designers, and builders here in Prescott, I can tell you: Yes, you can choose smart. Quartz gives you a path to long-lasting style if you know what to look for. Trends come and go. But the right quartz countertop has a quiet confidence to it; something that stays in step with shifting color palettes without ever looking tired. And that’s what I want to walk you through. Why Quartz Holds Up So Well Over Time One thing I’ve seen over the years is that subtle patterns age far better than bold ones. In a lot of the trendy colors hitting the market, manufacturers lock onto whatever’s popular in the moment—strong veining, big splashes of color, high contrast. And while those look great for the season, they can become the avocado-green appliances of tomorrow. But quartz designs with softer patterns . . . those stay right in the flow of design trends. They blend with light gray tones, warm whites, creams, golds—colors that continue to show up year after year in cabinets, backsplashes, and flooring. That subtlety gives you freedom to redesign a bathroom or kitchen around your countertop without replacing it every time you update paint or hardware. The Colors and Patterns That Stand the Test of Time In the last few years, we’ve seen grays fade a bit while white backgrounds and very light gray bases continue to stay strong. If you want something with staying power, that’s where I’d start. And quartz with a soft combination of gray and gold veining tends to be even more flexible—you can match that to warm woods, modern whites, painted cabinets, or natural finishes. Bold designs are fun, but subtle patterns are what I recommend for long-term durability of style. Here’s what I consider “safe bets” when you’re thinking long term: Light, soft-patterned quartz Whites with gentle gold or gray veining Cream tones with low contrast Very light grays that don’t pull too blue Patterns that mimic natural stone without being overly dramatic Those are the materials that “stay in the moving trends,” as I like to say. They evolve with your space rather than limiting your choices down the road. What About Other Finishes—Are They Trendy or Timeless? People sometimes ask whether finishes themselves—polished, honed, leathered, suede—come and go. In my experience, those aren’t falling in or out of favor as much as folks think. Polished is still the most common, but satin, matte, or suede finishes have carved out a solid place. A few things to know: Matte or suede quartz finishes look great, but they do take a little more attention to keep clean. Because of the micro-texture, they tend to “grab onto” stains more easily. They come out, but they take a bit more care. Darker quartz in matte finishes can show hard water deposits and oils more easily than lighter ones. Hard water is white, so it’s more visible on darker colors. Polished finishes are the easiest to maintain and still the most popular for busy kitchens. If you love the look of a matte finish, choose a lighter color and you’ll have a much easier time day to day. Choosing Smart Means Choosing What Works for Your Life Quartz gives you options—timeless options—when you know what to look for. I’m always going to steer people toward materials that give them long-term value. You’re investing in something you’ll see and touch every day. You want it to feel good five, ten, twenty years down the line. If you want to talk through the subtle patterns, the durable finishes, and the quartz designs that really do stay in style, bring a sketch and come see us in our Prescott showroom . We’ll help you explore what feels right and fits your space for the long haul. Designing Surfaces For Your Life

When people walk into our Prescott showroom and start talking flooring, one of the first questions that comes up is, “Can I put laminate in my kitchen or bathroom?” And the short answer is yes, you can—you just need to understand how today’s laminate is built and how to use it wisely in those moisture-heavy areas. I’ve been in this business a long time, and I’ve seen laminate evolve from something you’d avoid around water to a product that actually holds its own when it’s treated right. The newer materials are engineered with added oils in the wood, then pressure-treated with heat. That combination creates superior water resistance compared to the laminates we all grew up with. Still, like anything else in your home, it performs best when you give it a little support. Why Modern Laminate Handles Moisture Better Today’s laminate isn’t the same stuff people used twenty years ago. Manufacturers are using oils, pressure, and heat to help the core resist swelling. That means the occasional splash or spill isn’t the enemy it used to be. Now, if you pour water on it and walk away for hours, sure—you might see some damage. But in real-life living, where you’ve got a family coming and going and regular cleanups happening, it can hold up just fine. That’s why I tell people: laminate in kitchens and bathrooms isn’t something to be scared of. It just needs a few smart habits to stay in great shape. How to Protect Laminate in Kitchens and Bathrooms Moisture isn’t just about big spills. It’s the daily drips around your shower, the splash zone at the sink, and—let’s be honest—the mystery puddles that show up around the toilet. Here’s where planning makes a difference. I always recommend placing rugs in the high-moisture spots. That’s your first line of defense. Simple areas to protect with a small rug or mat: Right outside the shower In front of the bathroom sink Around the toilet In front of the kitchen sink In front of the stove (for cooking spills) These aren’t complicated solutions—they’re just practical. And they let laminate do what it’s designed to do without pushing it past its limits. Laminate in Kitchens: What to Expect Kitchens are high-traffic, high-function rooms. I’ve installed plenty of laminate in kitchens over the years, and what matters isn’t avoiding water altogether—it’s managing it. Putting a rug by the sink is an easy win, and I even like adding one in front of the stove. Not only does it help with spills, but it’s also more comfortable when you’re cooking. The good news is: regular use, daily cooking, wiping up splashes—these aren’t going to bother a modern laminate floor. Laminate in Bathrooms: Yes, It Works Bathrooms can feel trickier because there’s more standing water potential. But again, a little prevention goes a long way. Laminate is a perfectly good product for bathrooms as long as you place mats where they matter and don’t let puddles sit untouched for long stretches. I’ve seen families get years and years out of bathroom laminate by following these simple habits. It’s always about balancing beauty , durability , and lifestyle . If you love the look and feel of laminate, you don’t have to be afraid of using it in a bathroom. Final Thoughts: Make Your Home Work for You At the end of the day, laminate in wet zones comes down to smart choices and understanding how the material behaves. The newer laminates are built to resist moisture better than ever, and with just a little planning, they can be a durable, attractive option for your kitchen or bathroom. If you’re thinking about new surfaces—flooring, countertops, or anything in between—bring a sketch and come see us. We’ll walk you through the options that make sense for your home and your lifestyle. After 27 years in this business, we’ve “seen it all,” and we’re here to help you find what feels good. Designing Surfaces For Your Life

When you walk into a home that just feels right, where everything flows, the colors and textures speak to each other, and it all just fits, that’s not by accident. That’s the power of designer surfaces. Whether it's stone, tile, or flooring, the materials you choose do more than cover a countertop or a floor. They tell a story, your story. And when those materials are thoughtfully selected, they bring your custom home vision to life in a way that’s both personal and lasting. Here at Greenlee, that’s exactly what we help people do. It All Starts with Options (and Guidance) One of the things we’ve always focused on is giving people more options—especially when it comes to stone and tile. We know that can feel overwhelming at first. You walk into our showroom, and there’s a lot to take in. But that’s part of our process. We start with a conversation. We listen. We ask questions about your lifestyle, your space, your preferences. That little “interview” helps us understand what matters to you—what you like, what you don’t like, and what’s going to feel good in your home. From there, we help narrow it down and start guiding you toward selections that make sense for you. This isn’t about pushing a product. It’s about helping you create something meaningful with the right materials. Surfaces That Reflect Your Style Custom surfaces are one of the most impactful parts of a custom home. They’re where function meets form and where beauty meets durability. And they’re one of the best ways to reflect your personal style without saying a word. Whether you're drawn to the raw, natural movement of granite or the smooth consistency of quartz , whether you love bold tile backsplashes or subtle neutral tones, the surfaces you choose are going to define the tone of your space. We’ve seen homeowners light up when they find that one slab—the one with the veining that reminds them of driftwood, or the one with soft golds that tie their whole kitchen together. That’s when you know you’ve found the right surface. Why In-Showroom Matters You can browse pictures all day long, but there’s no substitute for seeing and touching materials in person. There’s something about walking the showroom and seeing firsthand how the light hits each slab, running your hand across the texture, feeling the weight and strength in the material. That’s why we do things the way we do. You’re not just ordering off a shelf. You’re choosing from curated inventory that we’ve hand-selected for quality, beauty, and variety. What Makes the Greenlee Experience Different We don’t believe in one-size-fits-all. When you come to Greenlee, you're getting: A deep inventory of natural and engineered materials you can view on-site Thoughtful guidance based on 27 years of experience In-house fabrication and installation (no hand-offs or outsourcing) Honest conversations about what will work best for your home and lifestyle A process that’s personal, not pushy There’s a reason we say: “Come see us.” Because once you do, you'll understand how different the experience can be when it's done right. Design That Lives With You We’re not just here to help you pick something pretty. We’re here to help you pick something that’s going to live with you, hold up to real life, and still make you feel good every time you walk in the room. That’s what design is really about, not trends, not hype, but choices that match your values, your routines, and your vision for your home. Bringing It All Together The materials you choose, the ones you cook on , gather around, walk across every day, they shape your home in ways you may not even realize. When they’re thoughtfully selected, when they’re fabricated with care, and when they’re installed the right way, they don’t just serve a purpose, they become part of the story you’re building in your space. So if you’re building or remodeling and want help finding the surfaces that truly reflect your custom vision, bring a sketch and come see us. We’ll help you find what makes you feel good. Designing Surfaces For Your Life Come see us.

When it comes to choosing the right flooring for your home, you’ve got a lot of great options and a lot of noise to sort through. Two of the most common choices we see homeowners considering are laminate flooring and engineered hardwood. Both can look fantastic. Both can last a long time. But they perform differently, install differently, and, maybe most important to many homeowners, they come with very different price tags. We carry multiple lines of laminate here at Greenlee, but today I want to highlight Hawkins Bay , a product line we’ve added to our showroom for good reason: it’s durable, cost-effective, and built for real life. Let’s break it down. Cost Comparison: Laminate Is the Clear Winner Let’s just start with the big one—cost. Engineered hardwood simply costs more, both in materials and in installation. If you’re on a tighter budget or need to cover a large space without compromising durability, laminate is going to stretch your dollar a lot farther. That said, price isn’t everything. It depends on what your goals are. If you're after a natural wood floor with unique, one-of-a-kind boards, engineered hardwood may be worth the investment. But if you're looking for a more budget-friendly material that still looks great and holds up well, laminate has come a long way. Installation: Floating vs. Glued Down There’s also a big difference in how these floors go in. Here at Greenlee, we prefer to install engineered wood as a floating floor, especially over concrete. It gives the wood room to breathe and reduces the risk of delamination between the finish species and the plywood subcore. Some folks still glue it down, but in our experience, gluing engineered wood to concrete creates a lot more stress on the material. I’ve seen more delamination issues with glued-down installs than with floating ones. Laminate, on the other hand, was made to float. Most laminate products, including Hawkins Bay, feature a click-and-lock system. There's no glue involved, and the boards just snap together. It's faster to install, and you can put a lot down in a single day. Durability and Moisture Resistance: Laminate Has Come a Long Way I’ll be honest, I used to think laminate might go the way of the dinosaur once vinyl plank hit the scene. And for a while, it looked like that might happen. But Hawkins Bay and other newer laminates have totally changed the game. Laminate is still a wood-based product, but it's no longer the sawdust-and-glue mix it used to be. Hawkins Bay uses an oil-based bonding agent and applies high heat and compression to create a core that’s much more resistant to moisture than older versions. Now, that doesn’t mean you can flood your kitchen and forget about it. You still have to pay attention to moisture, especially from underneath the floor. But the top surface of today’s laminate is extremely durable, in some cases, more durable than engineered hardwood or even vinyl plank. Comparing Core Stability: Laminate vs. Vinyl Plank I’m going to veer off course for a second here because this is something we see a lot in the field. Many folks ask us about vinyl plank floors, and while they can look nice, they come with their own set of issues—especially when the subfloor isn't perfectly flat. Vinyl planks are thin, and the locking mechanisms are small. If there’s any deflection or unevenness in your subfloor, those planks will come apart, and we end up going back to glue them together just to hold them in place. Laminate, on the other hand, tends to be thicker and has a more robust locking system. It’s more forgiving on slightly uneven floors and holds together better over time. Aesthetics: Uniqueness vs. Consistency Here’s where engineered hardwood really shines—no two boards are exactly the same. The grain, the knots, even how the tree grew in wet or dry years... all of that shows up in the finished product. It’s what makes wood floors feel warm and alive. Laminate is a manufactured product, so yes—you’re going to see some pattern repeats. But that’s not always a bad thing. In a big open space, consistency can actually be a good thing, especially when you’re trying to match colors or textures across a room. Here’s a quick rundown of how they compare: Engineered Hardwood Higher cost Real wood surface Unique grain in every board Susceptible to dents and scratches Can be refinished (depending on thickness) Laminate (Hawkins Bay) Lower cost Manufactured appearance with consistent patterns Extremely durable surface Moisture-resistant core Click-and-lock installation What We're Seeing in the Field Over the past few years, we’ve seen a steady shift back toward laminate especially the newer, high-performance options like Hawkins Bay. Many flooring professionals we talk to are choosing laminate over vinyl plank because of fewer callbacks, fewer failures, and better long-term performance. The advances in core technology and surface durability have really earned laminate its place back in the conversation. And for homeowners who want something durable, attractive, and budget-friendly, it’s becoming an easy choice. Choose What Makes You Feel Good The right floor isn’t just about price or performance, it’s about how it fits into your life. If you’ve got kids and dogs and don’t want to worry about every little scuff, Hawkins Bay laminate might be the perfect fit. If you love the feel of natural wood and want something truly one-of-a-kind, engineered hardwood is hard to beat. Whatever you’re leaning toward, come walk the showroom . We’ll show you the differences side-by-side, answer your questions, and help you figure out what makes you feel good when you walk through the door. Designing Surfaces For Your Life Come see us.

Share On: